- HOME

- Solution

- OmegaLand Educator

- Fluid Simulator

OmegaLand Educator Fluid Simulator

Users can learn principles and rules of process engineering efficiently.Aim of Fluid Simulator

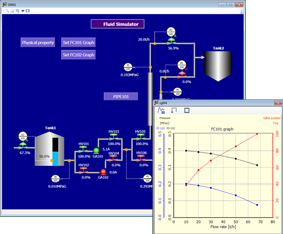

The purpose of this simulator is to learn about the basics of fluid transportation by carrying water through a pipe.

Using this simulator will enable:

- Calculating from a given mass flow rate and piping data, variables such as volumetric flow rate, average flow velocity, the Reynolds number, and pressure drops.

- Confirming that the physical properties of water are temperature dependent.

- Understanding the basics of heat balances from the data around the steam generator.

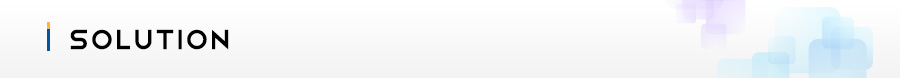

- By changing the flow rate setting, ensuring that the upstream and downstream pipe pressures and the degree of opening of the control valve change (by collecting and plotting various types of data, and checking the properties as a pattern).

Target Process

Water stored in a tank is fed to a tank that is installed in a higher place by two pumps with different performance characteristics and two pipes with different internal diameters (3B, 2B). In order to change the density of water, it is possible to change the temperature of the water.

Exercise Contents

- Find the pressure drop due to friction and the pressure drop according to the position when water flows at a fixed flow rate in pipe 3B.

- Maintain the water flow through this pipe 3B side, and fill in a data sheet with the pipe inlet pressure and outlet pressure and the degree of opening of the flow control valve when changing the flow rate of water. Plot the collected data in a graph.

- When the flow control valve is fully open, calculate the values of the water flow rate, the pipe inlet pressure, the pressure drop due to friction in the pipe at that time, the pressure according to the position, and the pressure drop in the control valve.

- Switch the flow path from pipe 3B to pipe 2B and perform the same exercises as in steps 1-3. Consider the effects due to the difference of the inner diameters of the pipes.

- HOME

- Solution

- OmegaLand Educator

- Fluid Simulator

Copyright © Omega Simulation Co., LTD. All Rights Reserved.