- HOME

- Solution

- OmegaLand Educator

- Distillation Tower Simulator

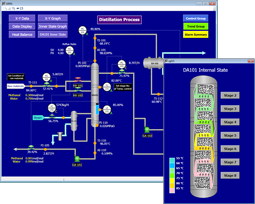

OmegaLand Educator Distillation Tower Simulator

Users can learn unit operations efficiently.Aim of Distillation Tower Simulator

The purpose of this simulator is to learn about topics such as distillation operation and control, and topics related distillation operation theory through the distillation separation process of a water-methanol mixture.

Using this simulator will enable learning about:

- Vapor-liquid equilibrium theory of the boiling point-composition diagram and x-y diagram, and theoretical stage models of the distillation column such as staircase diagrams.

- Changes in the tower temperature balance when varying the reflux ratio, and the effect of the reflux ratio.

- Calculation of the heat balance in the heat exchanger around the distillation column, and the effect of the impact of reflux ratio on the required heat load.

- Operation points due changes in operating conditions (such as temperature, reflux rate, steam flow rate).

Target Process

A mixture of water and methanol (30% molar content of methanol) is separated by evaporation in a distillation column which has 10 theoretical stages (including the reboiler). Steam of 0.8MPa (170C) is fed to the reboiler as a heating source, and the vapor outlet from the top of the tower is condensed by cooling water.

The control system around the distillation column includes control instruments installed for feed flow rate, tower temperature (cascaded with reflux flow rate), reflux ratio (cascaded with steam flow rate), and distillate and bottoms outflow rate control.

Exercise Contents

- In the cases of a reflux ratio of 1 and 4, examine how the internal tower temperature and the composition distribution change by plotting boiling point-composition diagrams and x-y diagrams.

- Examine how the internal tower temperature distribution changes by increasing or decreasing reflux flow rate.

- Examine the impact of the reflux flow rate, and investigate the temperature control of the distillation tower.

- Calculate the heat balance around the distillation column, the heat load of the reboiler, and condenser, and the required steam flow rate.

- Change the steam flow rate, and examine the change in the internal tower temperature, and the change required in reflux flow rate for temperature control.

- Investigate the relationship between variables such as the reflux flow rate, reflux ratio, and the steam flow rate.

- Examine the controllability of variables such as the tower temperature control and the reflux ratio control.

- HOME

- Solution

- OmegaLand Educator

- Distillation Tower Simulator

Copyright © Omega Simulation Co., LTD. All Rights Reserved.